Internal Structural Repairs Before the external work could happen considerable internal structural repairs needed to take place.Industrial rope access and rigging techniques were used to get the large sections of ironbark through the light fittings in the ground floor up into the spire. |

|

|

|

Once the timbers were in the spire, modern techniques combined with traditional carpentry methods were employed to make the necessary repairs. |

|

|

|

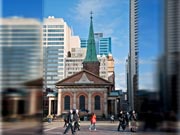

External repairs The old copper shingles had deteriorated at their seams and had already undergone repairs in the 1970’s. It was now time to renew the shingles altogether. But before that could happen, the timber sarking would need some repair. |

|

|

|

|

|

|

New copper work Great care was taken to make sure the patterns of the old copper work were replicated exactly in the new work. |

|

|

The existing bullseye windows were saved, and with some cleaning and repair they were installed into the new copper panels. |

|

|

|

|

Conservation of the Cross and Orb The Cross and orb were convict-built around 1821 and since then, seemingly due to access difficulties, had received no maintenance. Conserving these items was a welcome challenge, although not a simple one. |

|

Their structural condition as it turned out, was in real need of conservation. The original iron and timber superstructure had failed and would be replaced with stainless steel and nylon while the copper skin would be conserved and replaced un-polished. |

|

|

|

The deterioration of these items was such that we would have to lower them and carry out repairs in workshop conditions. |

|

|

|

We chose industrial rope access over conventional cranage as a means to convey the items to the ground as this provided the church with a substantial cost saving. |

|

|

|

|

|

After conservation works the cross and orb were reinstated using the same method. |

|

|

|